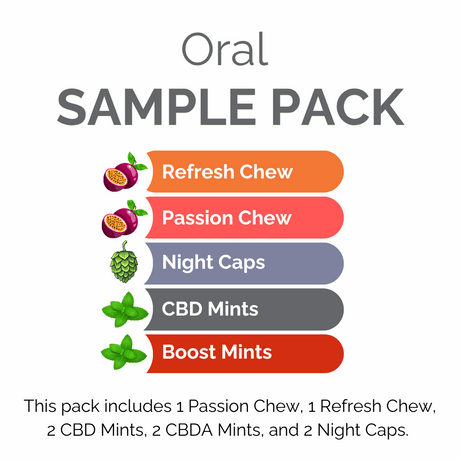

Recent momentum behind state-level legalization laws has transformed cannabis into the newest hot cash crop on the scene. Ask any good cook, and they'll tell you: that the secret to making great food is to start with great ingredients. But what if the ingredients you use changed significantly from day to day? How could you be sure about the quality of the food you serve? And what if, instead of preparing a great meal, your job is to prepare safe and quality products for distribution in the retail market? For companies that make products containing cannabinoids, these aren't just hypothetical questions. Cannabinoids are derived from cannabis and hemp plants; these crops are the most important raw ingredient in a wide range of products that are becoming more and more available – and popular – as laws change across the United States. But the cannabinoid content of cannabis and hemp plants can vary widely. Different growing conditions, different cultivars, and different harvest times can lead to significant unpredictability in the cannabinoid levels of the resulting crop, posing a huge challenge to companies that depend on that crop to make their products. Nailing Down a Moving Target Jessica Tonani and Kersten Beyer Gaba – founders of the Washingtonbased hemp research company Verda Bio, as well as Basic Jane, a company that produces CBD-containing consumer goods – set out to address this unpredictability at the source. They reasoned that making consistently high-quality end products had to start with producing consistent hemp and cannabis. "We created Verda Bio because we were convinced of the long-term benefits of cannabinoids," said Tonani. "In less than a decade, we went from being granted the first state-issued cannabis license in the country to working with growers to produce ~200k hemp plants last year alone. "When Agilent announced a competition where the grand prize was a year's free use of an Agilent HPLC for potency testing use, we jumped at the opportunity. When we learned we had won, "It was like winning the lotto!" Jessica Tonani and Kersten Beyer Gaba Founders Verda Bio More recently, we've created a new company, Basic Jane, to develop, manufacture, and deliver hemp-based products to consumers. But one of the challenges we've faced from the very start is that there simply aren't stabilized varieties of these plants available to study. Until those exist, it's difficult to get consistent, reproducible cannabinoid profiles out of the plants. There's just too much guesswork." Drawing on a background in genomics, Tonani set Verda Bio to the task of manipulating cultivar genetics, crossing plants to produce stable varieties. "Then we grew a lot of plants, produced a lot of seeds, and engaged local farmers to partner with us," she explained. "But the questions remained: what's the best way to look inside the plants and monitor cannabinoid production as growing conditions are optimized? How do we decide the time is right to harvest? And how do we demonstrate that these varieties deliver the consistent cannabinoid profiles we were aiming for, crop after crop?" Commercial testing labs using HPLC-based methodology gave Verda Bio the needed insight into their plants, but at a price. "Hiring a lab to do your testing can get expensive if your goal is to monitor multiple varieties of plants across multiple points in the growth cycle," Tonani said. "We test hemp starting at week four, then weekly through to harvest – maybe six or more tests per plant. With high-THC plants, we test a little less, maybe two to four times. So, it can definitely add up. There's also the question of turnaround time. Cannabinoid production is somewhat logarithmic, so a lag in testing results of just a day or two can lead to big changes in cannabinoid content. By the time you get your results, things inside the plant may be very different than when you took the sample, so that lag time becomes a pretty big issue. Also, commercial labs may have their methods set up to only look at certain compounds; adding new compounds to their analysis can involve a lot of development effort – and expense." Then there's the matter of transporting the samples. "For hemp, transporting samples to outside labs is fairly straightforward," Tonani explained. "Not so for cannabis. There are many added layers of regulation, paperwork, hassle, and expense involved just to get THC-containing samples to the lab for analysis. Having in-house testing can solve a lot of problems." Taking Control of Testing When Agilent announced a competition where the grand prize was a year's free use of an Agilent HPLC for potency testing use, Verda Bio jumped at the opportunity. When they learned they had won, "It was like winning the lotto!" Tonani said. "We were absolutely giddy thinking about all the things we were going to do with it." Bringing sophisticated, gold-standard cannabinoid analysis in-house might be expected to bring its own set of challenges, but Tonani and her colleagues at Verda Bio grew comfortable running the system within a couple of weeks. "We weren't as interested in becoming experts in the technology, the way an academic or pharma lab might be, so we faced a different kind of learning curve," she said. "We were really looking for certain answers – which we're getting." Beyond giving them more affordable and timely data, having around-the-clock access to HPLC has transformed their operations in some unexpected ways. "We've seen the benefits of being able to test using the same protocols every time, which can't always be guaranteed if you use multiple outside labs," Tonani continued. "It can become a significant issue when you are looking at cannabinoids in a finished product. We recently produced CBDA-containing mints and sent them off for testing to three different labs. Unfortunately, we got back three very different results, and we think it's because it isn't a matrix they were all equally familiar with. It's liberating for us to be able to set up our own methods to accommodate matrices that aren't as common – it's a vital part of being able to confidently offer our products to consumers. www.agilent.com/chem/cannabis Agilent products and solutions are intended to be used for cannabis quality control and safety testing in laboratories where such use is permitted under state/country law. DE06136314 This information is subject to change without notice. © Agilent Technologies, Inc. 2022 Published in the USA, May 17, 2022 5994-4957EN Besides that, having the HPLC makes it much easier for us to look for relatively minor cannabinoids a commercial lab may not report on or to look at a much lower level than they can offer. This opens up opportunities for us to explore creating new products with possibly unique effects." Hemp producers face an additional consideration – the "0.3% THC ceiling". Hemp crops that exceed this threshold THC limit run the risk of being confiscated and destroyed. Tonani feels this is another area where having in-house testing offers a competitive edge. "We've seen commercial labs that may have a 300% variability in their THC reporting. If a crop is close to the 0.3% THC threshold, that variability can mean the difference in a crop being retained or destroyed. It's a really crucial consideration." Lessons Learned Based on her experience bringing an Agilent HPLC into Verda Bio and Basic Jane, what advice would Tonani offer to others in the industry who might be considering adding in-house testing? "Having an Agilent HPLC has transformed our businesses in some really important ways," she said. "But for someone doing smaller grows, maybe only two or three rooms, bringing in an HPLC might be a lot for them to take on. For medium-sized and larger facilities, in-house testing could be ideal for them. And especially if a facility isn't just cultivating – for example, if they're producing oil – there is a lot of monitoring that should be done during that process. I think bringing in an HPLC should be a no-brainer for producer–processors.

https://www.agilent.com/cs/library/casestudies/public/casestudy-verda-bio-cannabis-5994-4957en-agilent.pdf